SCOTT INTERNAL BOND STRENGTH

Purpose of the test

This test is performed to determine the Scott Internal Bond Strength ofsolid board or folding board.

Procedure

Operate the instrument in accordance with ISO 536 and the manufacturer’s instructions.

Leave the samples exposed for 24 h to 23°C and 50% R.H., according to ISO 187.

From each test piece cut one test strip 25,4±0,2 mm x 25,4±0,2 mm². Each test strip provides five specimens, so you have one spare test strip.

Do not touch the test area with fingers.

Clean the angular element metal surfaces that come into contact with the adhesive tape.

The adhesive tape shall be according to: FINAT FTM1=15N/(25,4±0,2 mm).

Check that the instrument is level.

Ensure the minimum delay between the sample preparation and the test execution. Determine the internal bond strength taking into account only those tests where the delamination affected the whole specimen surface. If necessary, increase the pressure when preparing the specimen by using the appropriate distance spacers. Adjust and verify that the specimen preparation station exerts a pressure of 690±20kPa (100psi), the pressing period for these is 3,0±0,5 s.

Use the instrument low range to measure Level 1 and 2 samples, high range to measure Level 3 samples.

For instrument measures in ft · lb: ((ft · lb)/1000) · 2,102 = J/m².

Report 10 measures in J/m², their mean and standard deviation calculated to 3 significant figures.

Standards

UNI 9439

TAPPI T569

Nr. of samples

3 sheets (1 reserve) per Level.

Sample size 150 x 200 mm²

Special size L2-L3: 120 x 300 mm²

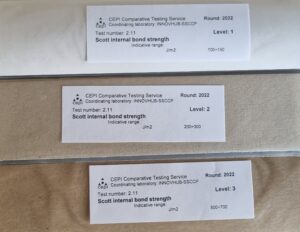

Levels

Level 1: 100÷150 J/m²

Level 2: 200÷360 J/m²

Level 3: 500÷800 J/m²

Reporting

Report 10 valid results of measurements in J/m², their mean and their standard deviation. All to three significant digits.